AIC Germany.

From competence to excellence.

Founded in 1975 as a two-man operation in the middle of Hamburg, Jürgen Liebisch GmbH has grown into a successful, medium-sized enterprise for the independent automotive aftermarket.

We trade our products worldwide and have evolved into a dynamic problem solver. Today, we operate from our state-of-the-art logistics centre in Glinde, near Hamburg. As Hanseatic businesspeople, we are characterised by our down-to-earth nature, authenticity and reliability. And service is paramount to us.

With our broad product portfolio spanning in excess of 100 product groups and more than 13,000 items, we create solutions for the independent aftermarket. Our top priority is and remains the successful combination of high-quality products and fair prices, ensuring that even older vehicles remain serviceable. We believe it is important to react flexibly to the needs of the market and to recognise new trends at an early stage. In doing so, we benefit from cooperative partnerships with our international network of suppliers and customers.

Besides our own high quality “AIC Germany” brand, in recent years we have also entered into sales cooperations with original equipment manufacturers. Our strong partners are:

Administration building and part of the warehouse complex of Jürgen Liebisch GmbH

QA and service exchange information

Quality is the cornerstone of our business

Quality and dependability are our top priorities in all areas – from the expertise of our employees and work processes to the maintenance of various partnerships with original equipment manufacturers such as iwis, Dunlop and Olsa. All this is supported by our sophisticated and TÜV-SÜD-certified quality management system. It is our goal to continuously improve quality and to systematically identify, analyse and reduce errors. This applies not only to our products and processes, but also to the people working in the company as well as our environment. We do everything we can to offer our customers a high-quality, suitable solution for the aftermarket.

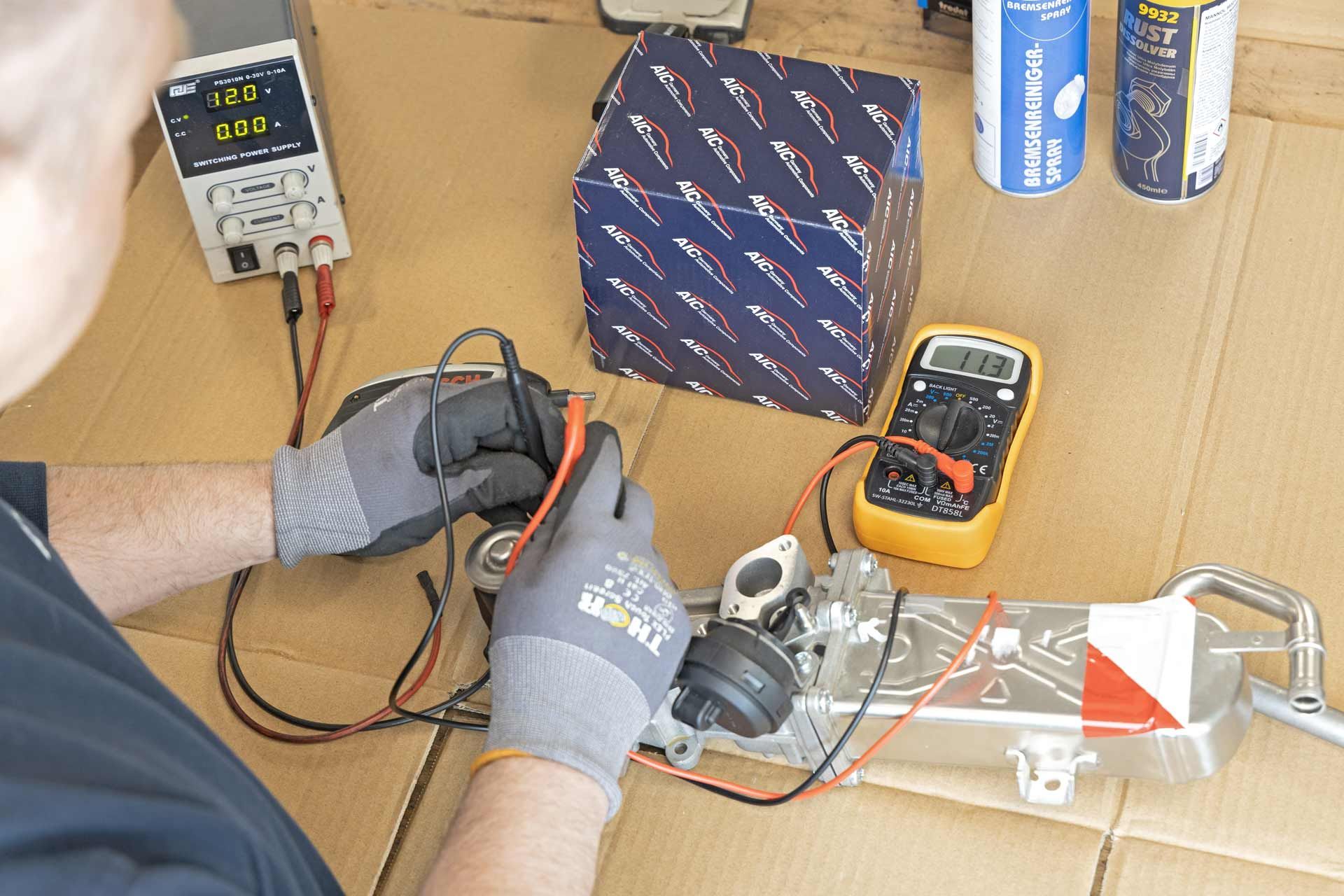

Quality inspection at AIC Germany

Pre-sampling

Each and every article goes through the process of pre-sampling. The same applies to any change of supplier. Dimensional accuracy, materials and function are checked in great detail on the basis of technical drawings, comparative samples of original spare parts and specific tests. Passing the pre-sample inspection is a prerequisite for the subsequent release of an item for procurement planning.

Incoming goods inspection

In the incoming goods area, each individual item is checked by our master mechanics on an item-specific and random basis. Only if the incoming goods inspection is successfully passed, will the item be released for sale.

Preparation for dispatch

When preparing the goods for dispatch to our customers, we again ensure that the type, quantity and condition of our items correspond to the information stored in the system. This is conducted in accordance with the four-eyes principle by two employees from the logistics department, each of whom checks independently of the other.

Once a spare part has passed all the checks, the ordered product can be delivered to the customer. After all, we at AIC want to be sure that the repair is completed smoothly. Should there ever be an instance where this is not the case, we also offer a warranty* of 5 years up to 75,000 km on all our spare parts from the AIC range. When the customers are satisfied, so are we.

* Applies to items from the installation date 01/01/2022 to the installation date 31/12/2025. Up to max. 75,000 km. Excluded from the warranty claim:: Follow-up costs, external influences, improper installation and wear and tear.

Product testing at the QA station

Our 4-stage quality process for completely satisfied customers

The forklift trucks always on their toes

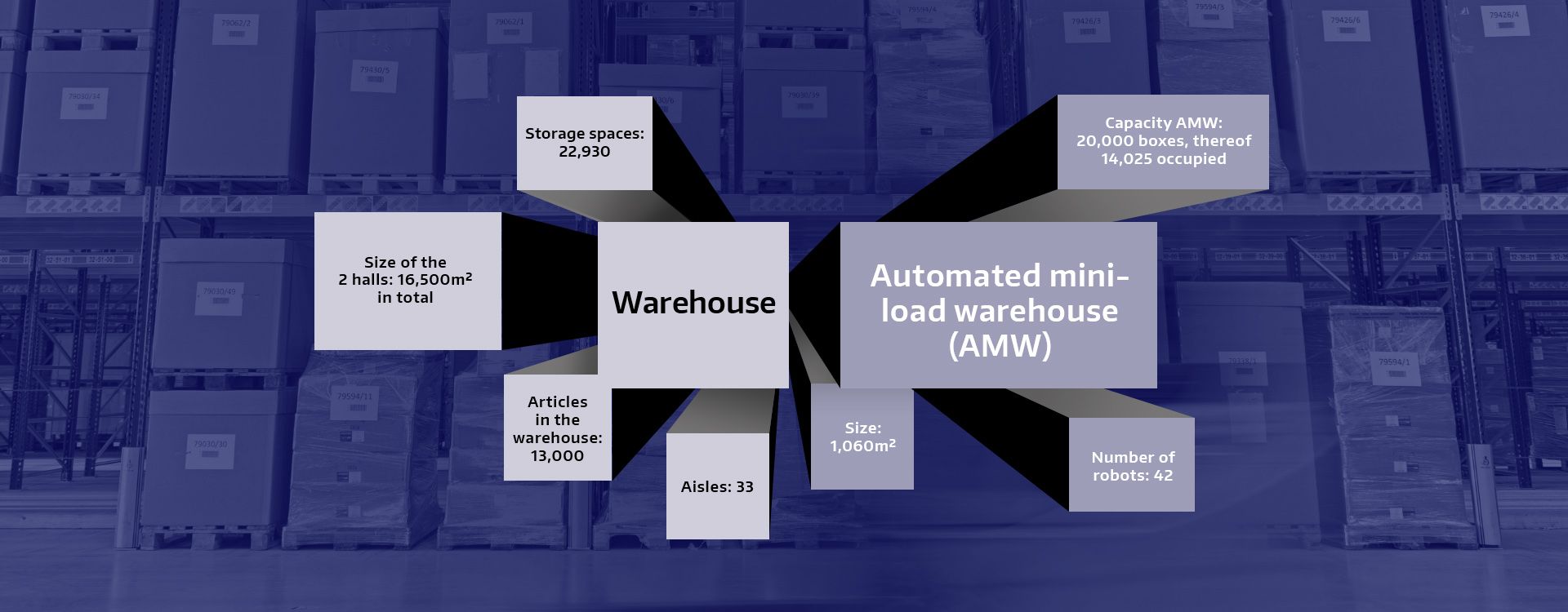

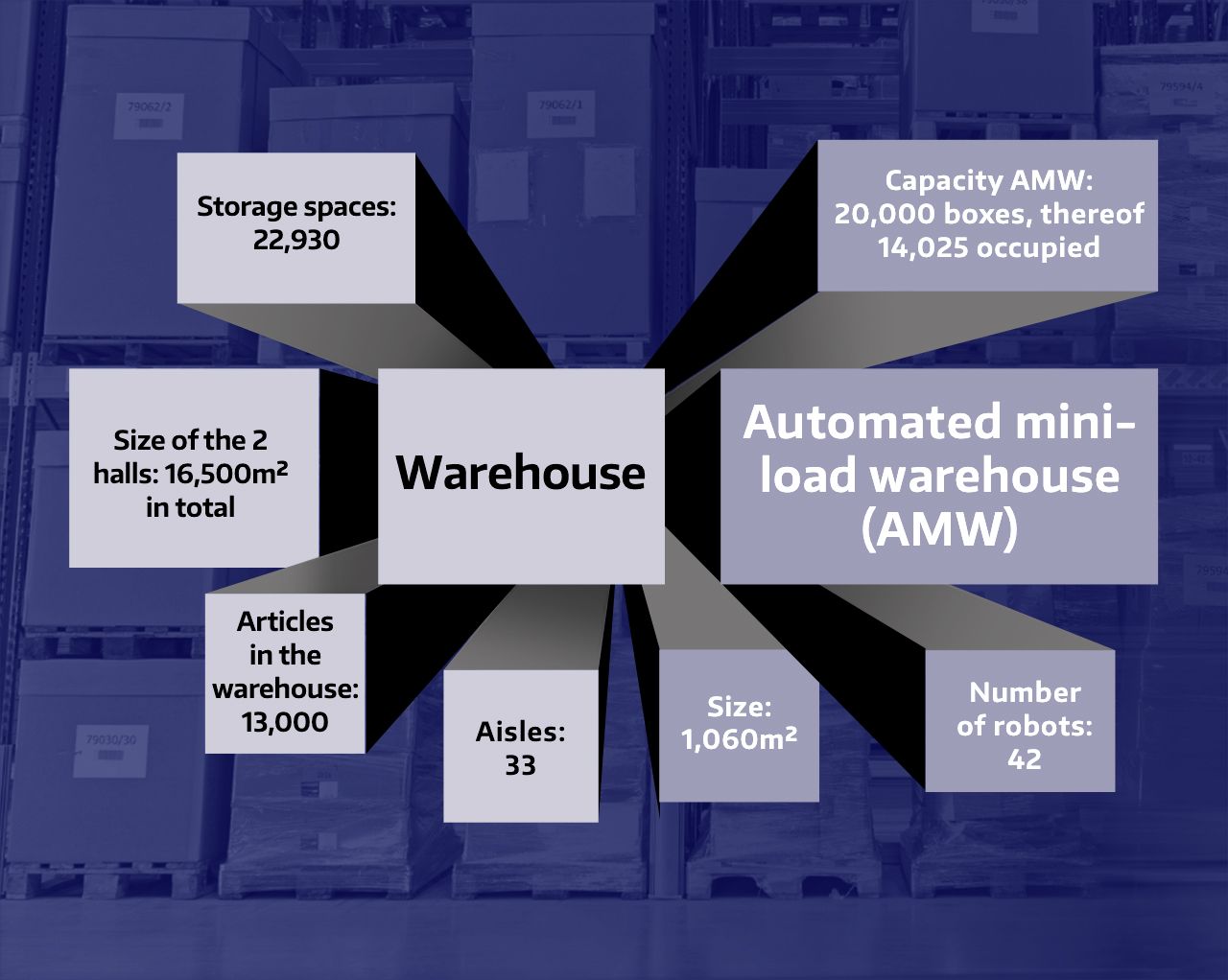

Warehouse and logistics

Several thousand automotive spare parts are stored and handled in our dynamic warehouse system every day. With the introduction of an automated small parts warehouse (AS/RS) in 2019, we can guarantee fast and efficient picking of small parts with the help of 42 robots. Storage and retrieval as well as order picking from our high-bay warehouse is performed by a wide range of industrial trucks such as narrow-aisle trucks, front and reach trucks and order pickers. We are especially proud of our latest investment: an automatic packing machine. In our parcel dispatch area, this automation will enable us to send hundreds of consignments a day in the future. When picking and packing, we pay special attention to the quality of the products and the safety of each individual employee in all our processes, applying the dual control principle.

Great value spare parts for five decades

-

1975:

Establishment of Jürgen Liebisch GmbH

-

1994:

Import of OE vehicle parts to Germany for all European car brands -

2004:

Launch of our own brand AIC Germany -

2016:

Relocation of the company headquarters to the new distribution centre in Glinde, near Hamburg -

2019:

Membership of ATR, expansion of the distribution centre by more than double the area, acquisition of a fully automated miniload warehouse

Contact

Jürgen Liebisch GmbH

Wilhelm-Bergner-Straße 11c

21509 Glinde

AIC Germany is a trademark of

Jürgen Liebisch GmbH.

Fon.: +49 40 253066-0

Fax: +49 40 253066-77

Email:

AIC products are exclusively distributed by wholesalers.

If you are a consumer or a car repair shop, please contact your local

vehicle parts dealer.